Chesterfield Sofa Frame Design: A Comprehensive Overview

The Chesterfield sofa, renowned for its timeless elegance and distinctive design, is a significant piece of furniture history. The frame, often unseen yet crucial, forms the very foundation of this iconic piece. A well-designed and constructed frame ensures the sofa's longevity, comfort, and adherence to the Chesterfield's recognizable aesthetic. Understanding the nuances of Chesterfield sofa frame design is essential for both manufacturers aiming to produce high-quality reproductions and consumers looking to invest in a durable and authentic piece.

The frame serves as the skeletal structure upon which all other components are built. It determines the overall shape, size, and structural integrity of the sofa. A poorly constructed frame can lead to sagging, instability, and premature wear, regardless of the quality of the upholstery and cushioning. The choice of materials, joinery techniques, and overall design considerations are paramount in creating a frame that can withstand the rigors of daily use and maintain its structural integrity for decades.

Key Material Considerations in Chesterfield Sofa Frames

The materials used in the frame construction significantly impact the sofa's durability and longevity. Historically, hardwoods have been the preferred choice for high-quality Chesterfield sofas due to their strength, stability, and resistance to warping. Oak, beech, and birch are commonly used examples. These hardwoods offer the necessary rigidity to support the weight of the upholstery, cushioning, and occupants.

The choice of wood also affects the sofa's weight. While hardwoods offer strength, they are also denser than softwoods. This increased weight can be a factor for consumers who anticipate frequent moving or rearranging of their furniture. Softwoods, such as pine, are less expensive and lighter but typically lack the long-term durability and structural integrity required for a lasting Chesterfield sofa frame. They are sometimes used in conjunction with hardwoods in less critical areas of the frame to reduce overall weight and cost.

Beyond the type of wood, the drying process is equally important. Kiln-dried wood is essential to minimize warping and cracking. This process reduces the moisture content of the wood, making it more stable and less susceptible to dimensional changes due to fluctuations in humidity. Failing to use kiln-dried wood can lead to significant structural problems over time, compromising the sofa's overall lifespan.

Modern frame construction may also incorporate engineered wood products such as plywood and oriented strand board (OSB) in certain areas. These materials can offer cost savings and dimensional stability, particularly in large, flat surfaces. However, the quality of engineered wood products varies widely. The use of high-quality plywood or OSB, properly installed and supported, can contribute to a strong and stable frame. However, the overuse of inferior engineered wood can compromise the sofa's longevity and overall value. The balance between cost, durability, and traditional construction methods is a key consideration for manufacturers.

Essential Joinery Techniques for Frame Stability

The strength and longevity of a Chesterfield sofa frame heavily rely on the joinery techniques used to connect the individual components. Historically, mortise and tenon joints have been favored for their exceptional strength and ability to withstand stress. This traditional method involves creating a projecting tenon on one piece of wood that is precisely fitted into a mortise (a hole or recess) on another piece. When glued and secured, the mortise and tenon joint provides a very strong and durable connection.

Dovetail joints, known for their interlocking design, are also frequently used, particularly in areas requiring high tensile strength, such as corners. The interlocking "tails" and "pins" of a dovetail joint create a mechanical bond that resists pulling forces. This type of joint is visually appealing and adds to the overall craftsmanship of the piece.

Dowelled joints, using cylindrical wooden dowels to connect pieces of wood, are another common method. While not as strong as mortise and tenon or dovetail joints, dowelled joints can be effective when properly executed with high-quality glue and precise alignment. They are often used in conjunction with other joinery techniques to reinforce weaker areas and provide additional stability.

The use of screws and nails should be supplementary to, not a replacement for, traditional joinery techniques. Screws and nails alone cannot provide the same level of long-term strength and stability as properly executed mortise and tenon, dovetail, or dowelled joints. Over-reliance on screws and nails is often indicative of cost-cutting measures and can compromise the sofa's structural integrity.

The quality of the adhesive used in the joinery process is also crucial. High-quality wood glue, specifically designed for furniture construction, is essential to create a strong and lasting bond between the frame components. The glue should be applied evenly and liberally to ensure proper adhesion and prevent future separation of the joints.

Design Considerations for Structural Integrity and Aesthetic Authenticity

The design of the Chesterfield sofa frame must consider both structural integrity and adherence to the traditional aesthetic. The frame should be designed to distribute weight evenly across the entire structure, preventing stress concentrations that can lead to premature wear and failure. Reinforcement of key areas, such as the arms, back, and base, is essential.

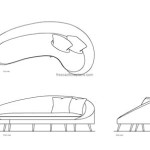

The iconic rolled arms of the Chesterfield present a specific design challenge. The frame must be carefully constructed to support the shape and weight of the rolled arms while maintaining their structural integrity. This often involves the use of curved or laminated wood components, carefully shaped and joined to the main frame structure.

The depth and height of the seat are also critical design considerations. The frame must be designed to provide adequate support for the seat cushions and occupants, ensuring a comfortable and stable seating experience. The placement and spacing of support rails within the frame are crucial in preventing sagging and maintaining the shape of the seat over time.

The back of the Chesterfield, typically characterized by its deep button tufting, requires a robust frame to withstand the tension created by the upholstery. The frame must be strong enough to support the tufting without warping or flexing, ensuring that the back maintains its shape and integrity. The design of the back frame often incorporates additional reinforcement and bracing to accommodate the stresses associated with the tufting process.

Furthermore, the legs of the Chesterfield must be securely attached to the frame and capable of supporting the entire weight of the sofa and its occupants. The leg attachment points should be reinforced to prevent them from breaking or becoming loose over time. The design of the legs themselves should also be in keeping with the overall aesthetic of the Chesterfield, contributing to its classic and elegant appearance. The design often includes considerations for weight distribution to prevent tipping or instability.

The overall geometry of the frame, including the angles and proportions of the various components, must be carefully considered to ensure that the finished sofa adheres to the traditional Chesterfield aesthetic. The frame should be designed to provide the correct shape and silhouette, allowing the upholstery to be applied smoothly and evenly, without distortion or bunching. Attention to detail in the frame design is essential to achieving a high-quality and authentic Chesterfield sofa.

In addition to the structural and aesthetic considerations, the frame design should also take into account the ease of upholstery and repair. A well-designed frame will allow for efficient and accurate upholstery, minimizing the risk of errors and ensuring a consistent and professional finish. The frame should also be designed to facilitate future repairs, allowing for easy access to the internal components and simplifying the replacement of damaged or worn parts. This consideration significantly extends the lifespan of the sofa and reduces the overall cost of ownership.

The long-term performance and value of a Chesterfield sofa are directly related to the quality of its frame. A well-designed and constructed frame, utilizing high-quality materials and proven joinery techniques, will provide a solid foundation for years of comfortable use. Understanding the key considerations in Chesterfield sofa frame design allows both manufacturers and consumers to make informed decisions and invest in pieces that will stand the test of time.

Crafting A Chesterfield Sofa Frame Plans Built In

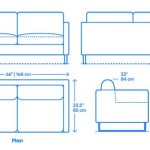

Image Result For Chesterfield Sofa Frame Plans Dimensions

Diy Chester Frame Making Part 1

The Anatomy Of Our British Made Chesterfield Sofas Timeless Chesterfields Blog

Pin On Diy

Top 216 Chesterfield Sofas Pictures Photos Wooden Sofa Designs Diy Frame

How To Make Chester Sofa Frame

Diy Chesterfield Sofa

Chesterfield Classic Sofa And Sectional Collection Buildasofa

Image Result For Chesterfield Sofa Frame Plans Como Hacer Un Medidas De Sillones Muebles En Crudo