European Sofa Manufacturers: A Landscape of Quality and Craftsmanship

The European sofa manufacturing industry represents a diverse ecosystem characterized by a commitment to quality materials, innovative designs, and skilled craftsmanship. Unlike mass-produced furniture often associated with other global regions, European manufacturers frequently prioritize durability, sustainability, and aesthetic appeal. This dedication translates into sofas that are not merely functional but also serve as enduring pieces of art and design within the home.

The industry's strength lies in a blend of established heritage brands and emerging design houses. Each contributes to a competitive landscape that drives innovation and elevates industry standards. Varying national styles and traditions also play a significant role, resulting in a wide range of sofa designs reflecting local preferences and cultural influences. From the minimalist Scandinavian aesthetic to the plush comfort of Italian designs, the European sofa market offers a diverse array of options to suit different tastes and interior design schemes.

The raw materials used are crucial to the longevity and quality of European sofas. Manufacturers often source high-grade timber for frames, ensuring structural integrity and resistance to warping. Upholstery fabrics are carefully selected for their durability, texture, and colorfastness, with many companies prioritizing natural fibers and sustainable production methods. Cushion fillings often involve a combination of high-density foam, feathers, and down, chosen to provide optimal comfort and support. The emphasis on premium materials contributes to a higher overall cost but results in a product designed to withstand years of use.

Technological advancements are increasingly integrated into the manufacturing process. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are used to optimize cutting patterns, minimize waste, and ensure precision in construction. However, the human element remains paramount. Skilled artisans are involved in various stages of production, particularly in upholstery, stitching, and finishing, ensuring attention to detail and a level of craftsmanship that automated processes cannot replicate. This blend of technology and handcraftsmanship is a defining feature of many European sofa manufacturing facilities.

Key Point 1: Material Quality and Sustainability

A defining characteristic of European sofa manufacturers is their unwavering commitment to sourcing high-quality materials. This not only impacts the overall aesthetic appeal and durability of the finished product but also reflects a growing emphasis on sustainability. Timber used for sofa frames is often sourced from sustainably managed forests, ensuring responsible forestry practices and minimizing environmental impact. Certifications such as the Forest Stewardship Council (FSC) are frequently sought to verify the origin and sustainability of the timber.

The selection of upholstery fabrics also reflects a commitment to both quality and sustainability. Many manufacturers are increasingly utilizing natural fibers such as linen, cotton, and wool, which are renewable resources and often biodegradable. Organic cotton and sustainably sourced linen are becoming increasingly popular choices, reflecting a growing consumer demand for eco-friendly products. Furthermore, manufacturers are exploring innovative materials such as recycled polyester and plant-based leather alternatives to minimize their environmental footprint.

The use of chemicals in the manufacturing process is also subject to increasing scrutiny. European regulations, such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), impose strict controls on the use of potentially harmful substances. Sofa manufacturers are actively working to replace traditional chemical treatments with more environmentally friendly alternatives, such as water-based finishes and natural dyes. This commitment to minimizing chemical exposure benefits both consumers and the environment.

The sourcing of fillings for sofa cushions also reflects a commitment to quality and ethical considerations. While synthetic foams remain a common choice due to their durability and affordability, many manufacturers are also utilizing natural fillings such as feathers and down. When using these materials, responsible sourcing practices are essential. Reputable manufacturers ensure that feathers and down are sourced from suppliers who adhere to strict animal welfare standards, avoiding practices such as live plucking. The use of recycled down and feathers is also becoming increasingly common, further reducing environmental impact.

Finally, the packaging used to transport sofas also receives attention from manufacturers focused on sustainability. Efforts are made to minimize the amount of packaging material used and to utilize recyclable or biodegradable materials whenever possible. Some companies are also exploring innovative packaging solutions such as reusable blankets and protective covers that can be returned and reused, further reducing waste.

Key Point 2: Design Innovation and Regional Styles

The European sofa manufacturing industry is characterized by a rich tapestry of design innovation, driven by diverse cultural influences and regional styles. Each country and region boasts its unique design aesthetic, contributing to the overall vibrancy and diversity of the European sofa market. From the minimalist functionality of Scandinavian design to the opulent elegance of Italian craftsmanship, the range of styles available reflects the diverse tastes and preferences of European consumers.

Scandinavian design, known for its minimalist aesthetic and functional simplicity, emphasizes clean lines, natural materials, and light, airy colors. Sofas designed in this style often feature exposed wooden frames, simple silhouettes, and upholstery in neutral tones. The focus is on creating comfortable and inviting spaces that promote relaxation and well-being. Scandinavian designers often prioritize practicality and durability, creating sofas that are both stylish and functional.

In contrast, Italian sofa design is often characterized by its bolder aesthetic, luxurious materials, and emphasis on comfort. Italian sofas frequently feature plush cushions, deep seating, and upholstery in rich colors and textures. The focus is on creating statement pieces that add a touch of elegance and sophistication to the home. Italian designers often experiment with innovative shapes and forms, pushing the boundaries of traditional sofa design.

French sofa design often blends classic elegance with contemporary sensibilities. French sofas frequently feature refined details, such as tufted upholstery, curved frames, and decorative accents. The focus is on creating timeless pieces that exude sophistication and charm. French designers often draw inspiration from historical styles, incorporating elements of Louis XV, Louis XVI, and Art Deco into their designs.

German sofa design often emphasizes functionality, durability, and precision engineering. German sofas are known for their clean lines, ergonomic designs, and high-quality materials. The focus is on creating comfortable and supportive seating that promotes good posture and relaxation. German designers often prioritize practicality and longevity, creating sofas that are built to last.

Emerging design trends are also shaping the European sofa market. Modular sofas, which can be configured in various ways to suit different spaces and needs, are becoming increasingly popular. Convertible sofas, which can be transformed into beds, are also in high demand, particularly in urban apartments and smaller homes. Sustainability is also a major driver of design innovation, with manufacturers exploring new materials and production methods to reduce their environmental impact.

Key Point 3: Skilled Craftsmanship and Manufacturing Techniques

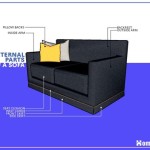

The reputation of European sofas is built not only on quality materials and innovative designs but also on the skilled craftsmanship and meticulous manufacturing techniques employed by manufacturers. The production of a high-quality sofa involves a complex process that requires a combination of skilled labor, precision technology, and attention to detail. From frame construction to upholstery and finishing, each stage of the process is carefully executed to ensure the highest standards of quality.

The construction of the sofa frame is a critical step in the manufacturing process. The frame provides the structural foundation for the sofa and determines its overall durability and stability. European manufacturers often use kiln-dried hardwood for their frames, which is more resistant to warping and cracking than softwood. The frame is carefully assembled using traditional joinery techniques, such as mortise and tenon joints, which provide a strong and durable connection.

The upholstery process is equally important. Skilled upholsterers carefully cut and sew the fabric to fit the frame, ensuring a smooth and even finish. They also attach the upholstery to the frame using a variety of techniques, such as stapling, tacking, and stitching. The upholsterer's skill and attention to detail are critical to achieving a professional and aesthetically pleasing result.

The cushions and fillings are also carefully selected and crafted. High-density foam is often used for the core of the cushions, providing support and durability. Layers of softer materials, such as feathers, down, or fiberfill, are then added to provide comfort and softness. The cushions are carefully stuffed and shaped to ensure a uniform appearance and optimal comfort.

Finishing touches, such as the application of decorative trim, the addition of buttons or tufts, and the polishing of wooden legs, are also important to the overall aesthetic appeal of the sofa. These details are carefully executed by skilled artisans, who take pride in their craft.

The use of technology plays an increasingly important role in the manufacturing process. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are used to optimize cutting patterns, minimize waste, and ensure precision in construction. However, the human element remains paramount. Skilled artisans are involved in various stages of production, ensuring attention to detail and a level of craftsmanship that automated processes cannot replicate.

High End Manufacturer European Style Sofa Home Furniture Whole U Shape Fabric Living Room Made In China Com

Whole Manufacturer European Leather Sofa With New Design Home Furniture Living Room Set Made In China Com

Fabric Velvet Linen On Tufted Chesterfield Luxury High End Leather Modern Classic Living Room American European Style Factory Sofa Couch Manufacturer Made In China Com

Linsy European Style Black And Gold On Tufted Chesterfield Sofa Set Rbj8k Manufacturers Home Furniture

Whole Manufacturer European Leather Sofa With New Design Home Furniture Living Room Set Made In China Com

Custom Classic Sofa Classical Furniture Manufacturers Kakaric

Modern Classic Contemporary Fabric Luxury Nail Head Living Room Leather Soft Comfortable American European Style Fine Home Furniture Sofa Factory Manufacturer Traditional Made In China Com

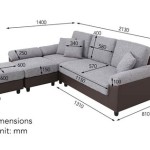

Buy European Style U Shape Sofa Set In Delhi Skf Decor Pvt Ltd

Modern Sofa Set Manufacturers In Gurgaon Whole Suppliers

Classic Fabric Diamond Tufted Chesterfield Tuxedo Nail Head Leather American European Style Living Room Couch Luxury High End Factory Sofa Manufacturer Modern Made In China Com