How to Make a Sofa Set Frame

Building a sturdy and well-constructed sofa frame is the foundation of a comfortable and long-lasting piece of furniture. This process requires careful planning, precise measurements, and appropriate woodworking techniques. This article outlines the steps involved in crafting a robust sofa frame.

Materials and Tools: Before beginning the construction process, gather the necessary materials and tools. Common materials include kiln-dried hardwood lumber such as oak, maple, or ash for the frame, plywood for the base, screws, wood glue, corner blocks, and webbing. Essential tools include a measuring tape, saw (circular saw or miter saw), drill, screwdriver, clamps, sandpaper, and a safety mask and goggles.

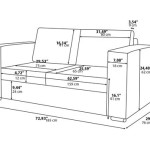

Design and Measurements: Begin by determining the desired dimensions of the sofa. Consider the overall length, width, and height, as well as the depth and height of the seating area. Create a detailed sketch or blueprint outlining these measurements. Accuracy in this stage is crucial to ensure a properly fitting frame.

Cutting the Frame Pieces: Using the established measurements, cut the lumber for the frame components. This includes the front and back rails, side rails, and legs. Ensure precise cuts at the correct angles, particularly if the sofa design incorporates angled arms or backrests. Double-check all measurements before making any cuts.

Assembling the Frame: Start by assembling the basic rectangular frame structure using the front, back, and side rails. Apply wood glue to the joining surfaces and secure the pieces together using screws. Clamps can be used to hold the pieces firmly in place while the glue dries. Reinforce the joints with corner blocks for added strength and stability.

Attaching the Legs: Once the basic frame is assembled, attach the legs. Ensure the legs are evenly spaced and securely fastened to the frame using screws and glue. The type of leg attachment will depend on the specific design of the sofa. Some sofa designs may incorporate a separate skirt or apron around the base.

Building the Seat Support: The seat support provides the foundation for the cushions. This typically involves creating a platform using plywood or closely spaced wooden slats. The support should be securely attached to the frame rails, ensuring it can bear the weight of the cushions and users. Adequate support is crucial for preventing sagging and ensuring long-term comfort.

Adding Back Support: Construct the back support frame using the same techniques as the main frame. The design of the back support will depend on the style of the sofa. It may be a solid panel, individual slats, or a combination of both. Attach the back support securely to the main frame, ensuring proper alignment and stability.

Reinforcements and Bracing: Add extra reinforcement and bracing to critical areas of the frame, particularly at joints and corners. These reinforcements can include additional corner blocks, cross braces, or metal brackets. These additional supports enhance the overall strength and durability of the sofa frame.

Sanding and Finishing: Once the frame is fully assembled, sand all surfaces smooth to remove any rough edges or splinters. This prepares the frame for upholstery. The type of finish will depend on the desired aesthetic and the type of upholstery fabric being used. Some common finishes include painting, staining, or sealing the wood.

Webbing and Padding Preparation: Before attaching the upholstery fabric, install webbing across the seat and back supports. This webbing provides a flexible base for the cushions and helps distribute weight evenly. After the webbing is installed, add layers of padding, such as foam or batting, to create the desired level of comfort and shape.

Frame Construction Variations: While the basic principles remain consistent, specific construction techniques may vary depending on the sofa design. Sectional sofas, for example, will require additional framing considerations to accommodate the modular sections. Similarly, sleeper sofas will require a specialized frame to incorporate the folding mechanism.

Wood Selection and Quality: The choice of wood significantly impacts the strength and durability of the sofa frame. Kiln-dried hardwood is generally preferred for its stability and resistance to warping. Ensure the lumber is free from knots, cracks, and other defects that could compromise the structural integrity of the frame. High-quality wood contributes to a longer-lasting and more robust sofa.

Safety Precautions: Throughout the construction process, prioritize safety. Always wear appropriate safety gear, including a dust mask and eye protection. Use power tools cautiously and according to manufacturer instructions. Ensure the work area is well-ventilated and free from clutter. Taking the necessary safety precautions will prevent accidents and ensure a safe working environment.

How To Make A Sofa Frame Step By Guide An Seating Chart Tips Tricks In 2024 Corner Design

How To Make Rib Model Sofa Frame Leather Set Design Letest

Diy Modern Sofa Set Frame Making

How To Make Leather Chester Sofa Frame Modern Set Making Wood Wooden

How To Make Fabric Sofa Frame Simple Tips And Tricks New Latest 2024 Making

How To Make Sofas Diy Quora

How To Make Low Cost High Quality Sofa Frame Making Process Simple Sofas

How To Make Studio Couch Wood Structure

How To Make 9 7 Corner Sofa Frame Designs L Diy

Part 2 How To Make A Damro Model Sofa Set Frame Making Latest Designing Best Quality