Making a Sofa Frame: A Comprehensive Guide

The sofa frame serves as the foundational structure for any upholstered seating. Its strength, stability, and design directly influence the long-term durability, comfort, and aesthetic appeal of the finished piece. Constructing a robust and well-designed sofa frame requires careful planning, precise execution, and a thorough understanding of woodworking principles. This article provides a comprehensive overview of the process involved in making a sofa frame, outlining essential materials, tools, techniques, and considerations.

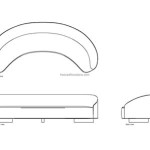

Before commencing the construction process, a detailed plan incorporating precise measurements and design specifications is paramount. This plan should encompass overall dimensions, seat height, back angle, armrest style, and the intended upholstery method. Careful consideration should be given to the anticipated weight load and usage patterns to ensure the frame's structural integrity. A well-defined plan serves as a blueprint, minimizing errors and ensuring a cohesive and professional outcome.

Key Point 1: Material Selection and Preparation

The selection of appropriate materials is crucial for the longevity and performance of the sofa frame. Hardwoods, such as kiln-dried maple, oak, or birch, are generally preferred due to their inherent strength, stability, and resistance to warping. Softwoods, like pine, can be used for less critical components, but are typically avoided for structural elements that bear significant weight. In addition, the type of material used will correlate to the style of the sofa being built.

Before commencing any cutting or assembly, the chosen lumber must be thoroughly inspected for defects, such as knots, cracks, or excessive warping. Any compromised pieces should be discarded or repurposed for less structurally significant applications. Kiln-dried lumber is essential; it has been processed to reduce its moisture content, minimizing the risk of shrinkage or expansion after assembly, which can lead to joint failure and structural instability.

Accurate measurement and precise cutting are essential for a well-fitting and structurally sound frame. A measuring tape, square, and marking gauge should be used to ensure accuracy. A miter saw, table saw, or circular saw can be employed for cutting the lumber to the required dimensions. The choice of saw will depend on availability, specific cut requirements, and desired level of precision. All cuts should be clean and square, with no splintering or rough edges. Safety precautions, including wearing safety glasses and using appropriate guards, should be strictly adhered to during all cutting operations.

Lumber should be planed to achieve a uniform thickness and smooth surface. This ensures that all frame components are consistent and that joints will fit together seamlessly. A jointer can be used to flatten one face of the lumber, followed by a planer to achieve the desired thickness and surface finish. Proper dust collection is essential when using these machines to maintain a safe and healthy working environment.

Sanding the lumber before assembly further enhances the smoothness of the surfaces and prepares them for gluing and finishing. Start with a coarser grit sandpaper (e.g., 80-grit) to remove any imperfections and then progress to finer grits (e.g., 120-grit, 220-grit) for a smooth, paintable surface. Thoroughly remove any sanding dust before proceeding to the assembly stage.

Key Point 2: Assembling the Frame Structure

The assembly process involves joining the various frame components together to create a rigid and stable structure. A variety of joinery techniques can be employed, each offering different levels of strength and aesthetic appeal. Common joinery methods include mortise and tenon joints, dowel joints, pocket screw joints, and butt joints reinforced with screws and glue. The choice of joinery method depends on the specific application, the type of lumber being used, and the desired level of durability.

Prior to gluing and fastening, dry-fitting the frame components is essential to ensure accurate alignment and proper fit. This allows for any necessary adjustments to be made before the adhesive is applied. Clamps should be used to hold the components together during the dry-fit, simulating the pressure that will be applied during the gluing process. Any discrepancies or misalignments should be addressed before proceeding.

High-quality wood glue should be used for all joints to ensure a strong and durable bond. The glue should be applied evenly to both joining surfaces and then clamped together tightly. Excess glue should be wiped away with a damp cloth to prevent it from drying and interfering with the finishing process. The clamped assembly should be allowed to cure for the manufacturer’s recommended time, typically 24 hours, before removing the clamps.

Screws, nails, or staples can be used to reinforce the glued joints, providing additional strength and stability. The type and size of fastener should be appropriate for the thickness of the lumber and the type of joint being reinforced. Screws are generally preferred over nails or staples, as they provide a stronger and more reliable hold. Ensure that the fasteners are driven in straight and flush with the surface of the lumber to prevent them from interfering with the upholstery process.

Corner blocks can be added to the inside corners of the frame to further enhance its strength and rigidity. These blocks should be made from hardwood and glued and screwed into place. They provide additional support and prevent the frame from racking or twisting under stress.

Key Point 3: Reinforcement and Support Elements

To ensure the long-term durability and comfort of the sofa, additional reinforcement and support elements are often incorporated into the frame design. These elements help distribute weight evenly, prevent sagging, and provide a stable foundation for the cushions and upholstery.

Webbing or sinuous springs are commonly used to provide support for the seat cushions. Webbing is typically made from interwoven strips of elastic or non-elastic material, while sinuous springs are metal springs that are shaped in a zig-zag pattern. Both methods provide a resilient and comfortable seating surface. The choice between webbing and sinuous springs depends on the desired level of support, the type of cushions being used, and the overall design of the sofa.

When using webbing, it should be securely attached to the frame with staples or specialized webbing clips. The webbing should be stretched tightly and evenly to provide uniform support. The spacing between the webbing strips should be determined based on the weight and density of the cushions.

Sinuous springs are typically attached to the frame with spring clips and screws. The springs should be spaced evenly and securely fastened to prevent them from shifting or sagging. Additional reinforcement, such as metal bands or wooden slats, may be required to support the springs and distribute weight evenly.

Center supports or cross rails can be added to the frame to provide additional support for the seat and back. These supports should be made from hardwood and securely fastened to the frame with screws and glue. They help prevent the frame from flexing or sagging under heavy use.

Armrests should be securely attached to the frame with screws and glue. Additional bracing may be required to provide adequate support and prevent the armrests from wobbling or breaking under pressure. The design and construction of the armrests should be consistent with the overall aesthetic of the sofa.

Legs are an integral part of the sofa frame, providing both structural support and aesthetic appeal. The legs should be securely attached to the frame with screws, bolts, or specialized leg brackets. The type of leg attachment method depends on the style of leg and the overall design of the sofa. Ensure that the legs are properly aligned and level to prevent the sofa from rocking or wobbling.

Once the frame is fully assembled and reinforced, it should be thoroughly inspected for any defects or weaknesses. All joints should be secure, and the frame should be stable and level. Any necessary repairs or adjustments should be made before proceeding to the upholstery stage. A well-constructed sofa frame will provide a solid and durable foundation for years of use.

How To Make 9 7 Corner Sofa Frame Designs L

How To Make A Sofa Frame Step By Guide An Seating Chart Tips Tricks In 2024 Corner Design

How To Make 9 7 Corner Sofa Frame Designs L

How To Build A Sofa Couch Built In Your Own

How To Make Sofas Diy Quora

Diy Modern Sofa Set Frame Making

How To Make Studio Couch Wood Structure

Building A Club Couch From Scratch

Home Dzine Diy How To Make An Upholstered Sofa Or Couch

How To Make Chester Sofa Frame