Stainless Steel Sofa Leg Manufacturers: A Comprehensive Guide

Stainless steel sofa legs have become increasingly popular in contemporary furniture design. Their durability, sleek aesthetic, and resistance to corrosion make them a preferred choice for manufacturers and consumers alike. This article will explore the key aspects of stainless steel sofa leg manufacturing, providing insights into material selection, manufacturing processes, and quality considerations.

Material Selection: Grades and Properties

The selection of stainless steel grade is paramount in determining the performance and longevity of sofa legs. Commonly used grades include 304 and 316. Grade 304 offers excellent corrosion resistance and is suitable for indoor applications. Grade 316, with its higher molybdenum content, provides enhanced resistance to chlorides and other corrosive agents, making it suitable for outdoor or coastal environments. The chosen grade directly impacts the leg's structural integrity, resistance to rust, and overall aesthetic appeal.

Manufacturing Processes: From Raw Material to Finished Product

Manufacturing stainless steel sofa legs involves a series of carefully executed processes. The initial stage often involves cutting the stainless steel into the desired lengths using techniques like laser cutting or waterjet cutting. These methods ensure precision and minimize material waste. Subsequent processes may include bending or shaping the steel to achieve the intended design. Welding, if required, is performed using techniques suitable for stainless steel, ensuring strong and seamless joints. Finally, the legs undergo finishing processes like polishing or brushing to achieve the desired surface appearance.

Finishing Techniques: Enhancing Aesthetics and Durability

Finishing processes play a crucial role in enhancing the aesthetic appeal and durability of stainless steel sofa legs. Polishing creates a highly reflective, mirror-like finish, while brushing provides a more subtle, satin-like appearance. Powder coating can also be applied, adding a layer of color and further protection against scratches and wear. These finishing options allow manufacturers to offer a diverse range of styles and cater to various design preferences. Proper finishing also contributes to the longevity of the legs, protecting them from environmental factors and daily wear and tear.

Quality Control: Ensuring Strength and Durability

Maintaining stringent quality control throughout the manufacturing process is crucial for ensuring the strength, durability, and overall quality of the finished product. Regular inspections should be conducted at each stage, from raw material procurement to final finishing. Testing procedures, such as load-bearing tests and corrosion resistance tests, are essential for verifying that the legs meet the required standards. Rigorous quality control measures ensure that the finished product meets customer expectations and provides lasting performance.

Customization Options: Tailoring to Specific Needs

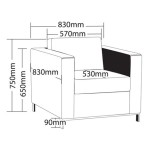

Many stainless steel sofa leg manufacturers offer customization options, allowing furniture designers and manufacturers to create unique and bespoke pieces. Customization can include variations in leg height, diameter, shape, and finish. This flexibility allows for a seamless integration of the legs into the overall furniture design, ensuring a cohesive and aesthetically pleasing final product. The ability to customize stainless steel sofa legs provides designers with greater creative freedom and allows them to cater to specific project requirements.

Sustainability Considerations: Environmental Impact

Sustainability is an increasingly important consideration in manufacturing. Stainless steel, being a highly recyclable material, aligns well with sustainable practices. Manufacturers can minimize their environmental impact by utilizing recycled stainless steel in their production processes. Furthermore, implementing efficient manufacturing techniques that reduce waste and energy consumption contributes to a more sustainable approach to sofa leg manufacturing.

Partnering with a Reputable Manufacturer: Key Factors

Choosing the right stainless steel sofa leg manufacturer is essential for ensuring product quality and reliability. Factors to consider when selecting a manufacturer include their experience, manufacturing capabilities, quality control processes, and commitment to sustainability. A reputable manufacturer will possess the expertise and resources to produce high-quality stainless steel sofa legs that meet specific design and performance requirements. Building a strong partnership with a reliable manufacturer contributes to the success of furniture projects and ensures customer satisfaction.

Stainless Steel Sofa Leg

Stainless Steel Sofa Legs

Round Sofa Leg 45 Mm In Bulk Stainless Steel 202 4 Piece

Silver Chrome Finish 3inch Stainless Steel Sofa Legs

Stainless Steel Round Sofa Leg At Rs 45 Piece In Ahmedabad Bhoomi Fabrication

Stainless Steel Sofa Leg Supplier Manufacturer From Rajkot Mumbai Paras Industries Enterprise Minimal Furniture Legs

Manufacturer New Style Sofa Leg Parts Steel Chrome Metal Furniture Feet China Contemporary Legs Made In Com

Krishna Industries Manufacturer Of Stailess Steel Sofa Leg Ss Fancy Premium Holder Metal Brackets Sofaleg Cornner Best

65mm Stainless Steel Sofa Leg

Buy Plantex Heavy Duty Stainless Steel 4 Inch Sofa Leg Bed Furniture Pair For Home Furnitures Dts 51 Chrome Pcs At Best S In Jiomart